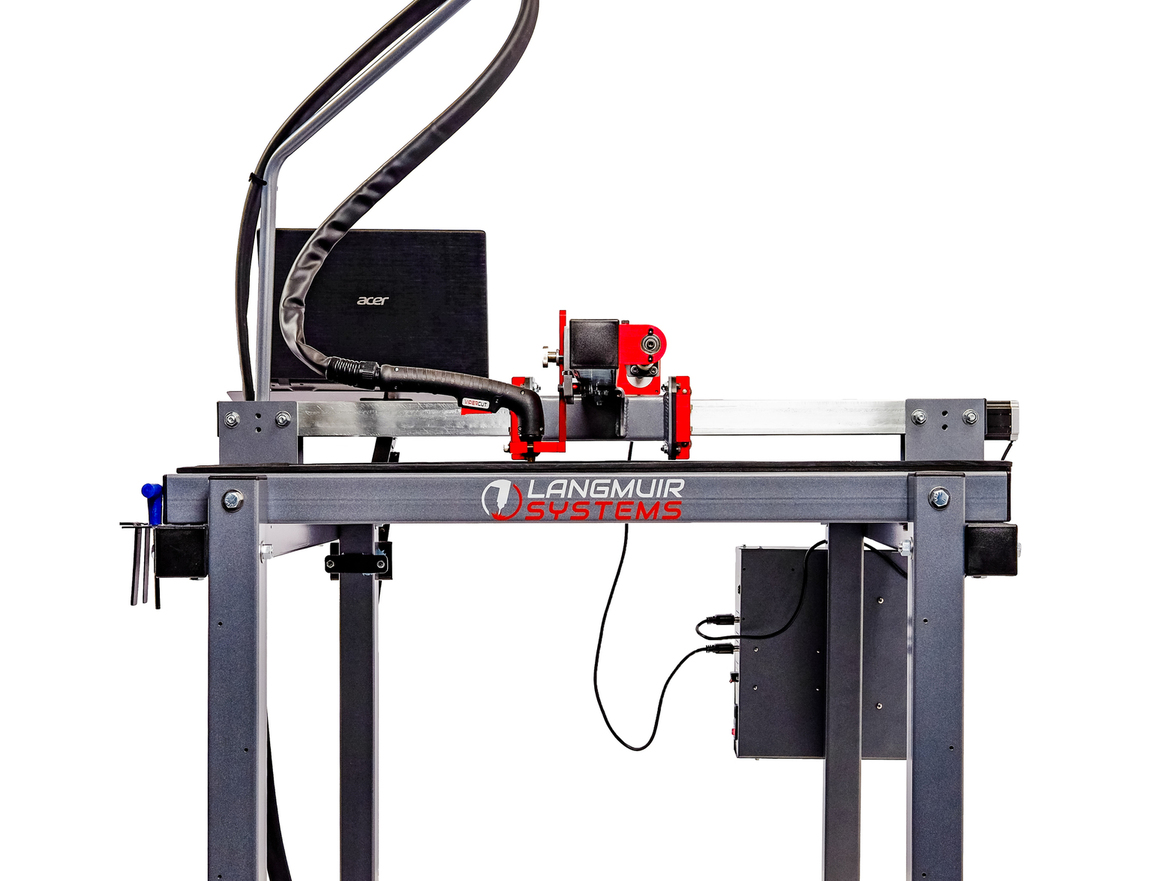

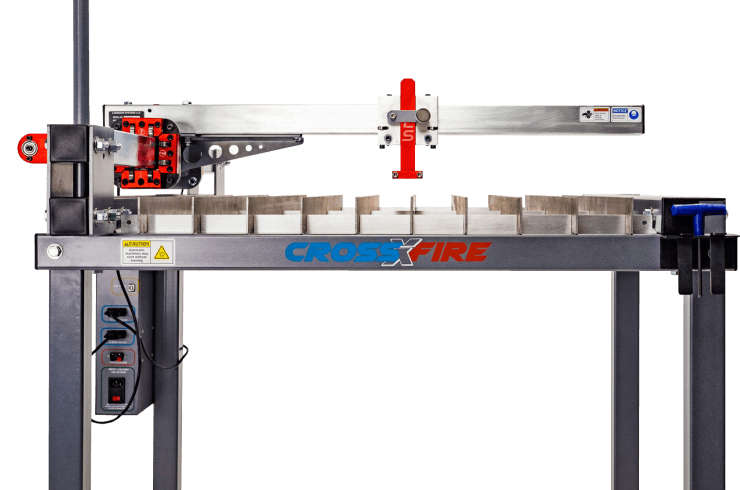

CANTILEVERED GANTRY SYSTEM

The CrossFire™ CNC plasma machine features a fully cantilevered gantry system for torch movement which allows for complete and unhibited access to the cutting surface for a wide variety of plate shapes and sizes. By indexing material through the machine, the CrossFire™ is capable of cutting much larger sheets of material through subsequent setup operations.

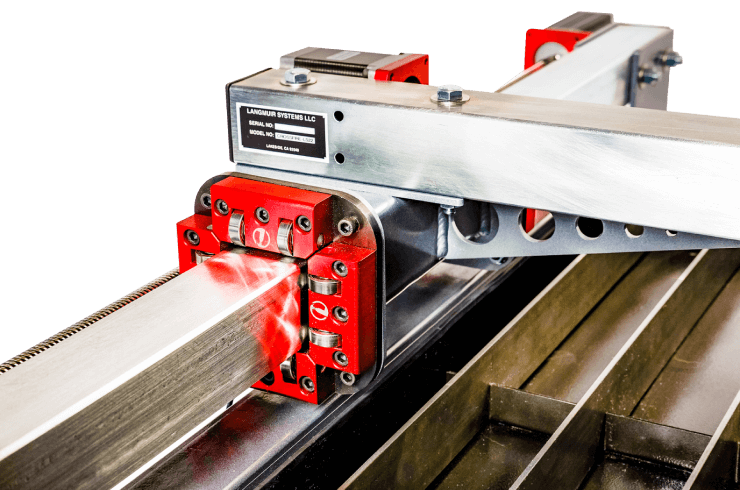

BILLET ALUMINUM TORCH CARRIAGE

The torch carriage on the CrossFire™ was designed to be lightweight and accurate for smooth motion on the cantilevered gantry. The torch carriage is CNC machined from aircraft-grade 6061-T6 billet aluminum and the torch slide assembly is anodized red for a finished look.

USB CONNECTIVITY

No more are the days of needing an old computer with a parallel port to run your CNC machine. The CrossFire™ electronics enclosure comes standard with a USB port for quick and easy connectivity to your computer. The CrossFire™ CNC plasma machine is compatible with any computer running Windows XP/Vista/7/8/10.

QUICK ADJUST MANUAL TORCH HEIGHT

The torch carriage assembly features a stainless steel thumb screw on the torch slide for quick and easy torch height adjustment.

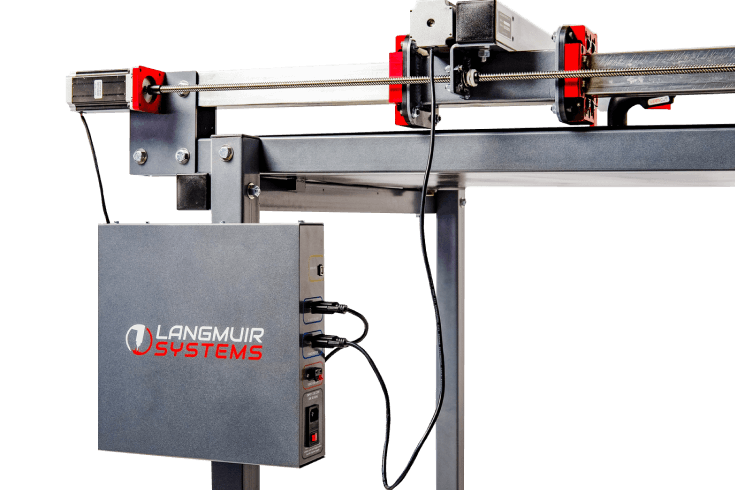

ZINC ELECTROPLATED RAIL SYSTEM

The CrossFire CNC plasma machine features a dual rail drive system manufactured from zinc electroplated steel tubing for maximum corrosion protection.

UNIVERSAL V-BLOCK TORCH MOUNT

Each machine comes equipped with a universal V-block torch mount which can accept any standard hand or machine plasma cutting torch.

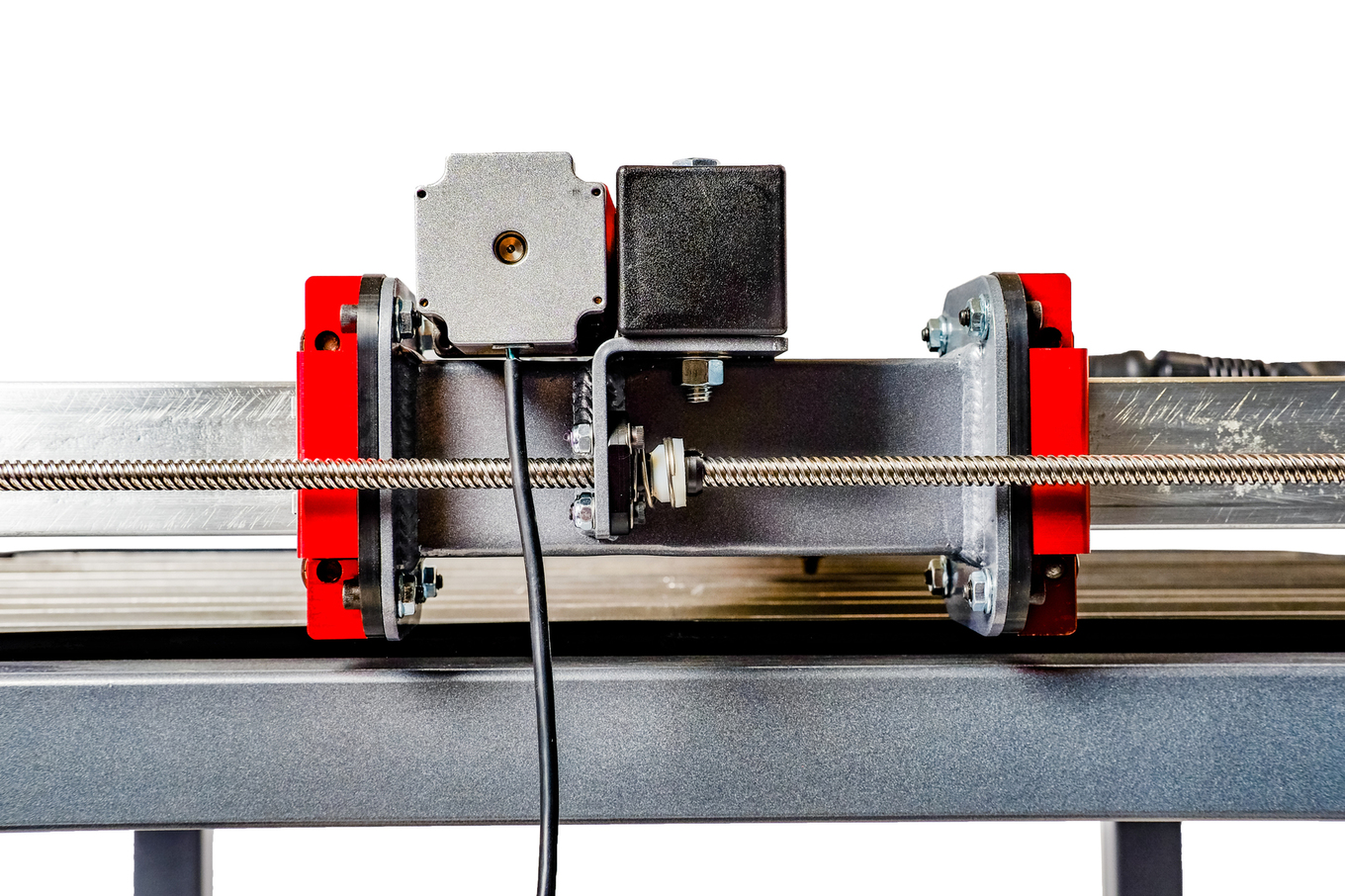

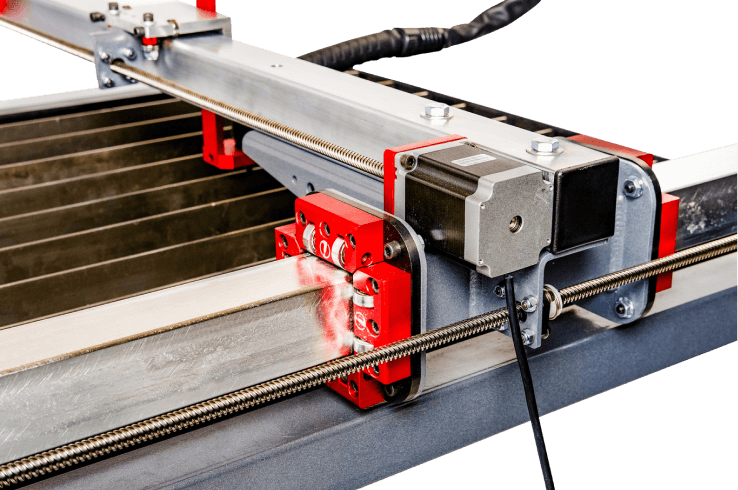

MULTISTART LEAD SCREWS & ANTI-BACKLASH LEAD NUTS

Each machine drive system comes equipped with two precision multi-start lead screws coupled with two anti-backlash wear compensating lead nuts. The aggressive pitch of the multi-start lead screws allows for maximum travels speeds of 250 inches per minute while maintaining peak motor torque. With the wear compensating anti-backlash lead nuts, you'll never have to make micro-adjustments to your setup over time.

INDUSTRIAL BALL BEARING CARRIAGE DESIGN

Both X & Y axes carriages come equipped with full size double shielded industrial ball bearings for smooth and accurate motion. The X axis gantry carriage includes a total of 16 ball bearings while the Y axis torch carriage includes 8.

HEAVY DUTY POWDERCOATED STEEL FRAME

The rigid all-steel construction features structural tubing and vertical plate stanchion supports for increased strength. In addition, the unique triple-pocketed frame design provides for a stiff table surface that can support steel plate material up to 1" thick. Each steel component on the frame is powdercoated metallic gray for a long-lasting and wear resistant finish.

ELECTRONIC TORCH FIRING SYSTEM

The integrated electronics system features an input for automatic torch firing. This sysytem allows the computer control software to automatically fire the plasma torch at the start of each cut when executing a program. Simply wire up your plasma cutter and start cutting!

TORCH QUICK RELEASE AND HEIGHT SHIMS

Each machine includes a leg mounted T-handle hex key for quick release of the plasma torch. This makes it quick and easy for removing the hand torch from the V-block mount when making manual cuts off the machine. In addition, two height-offset shims are included for quick torch cut-height adjustment.

OPEN SLAT SURFACE

The CrossFire™ was designed with an open slat surface that sits flush to the steel tube frame. This permits open access to much larger plates and allows for material to be clamped directly to the tube frame when cutting.

ROLLING TABLE WITH SWIVEL LOCK CASTERS

The CrossFire™ was designed with an open slat surface that sits flush to the steel tube frame. This permits open access to much larger plates and allows for material to be clamped directly to the tube frame when cutting.

HIGH TORQUE BIPOLAR STEPPER MOTORS

The CrossFire™ features two high torque hybrid bi-polar stepper motors manufactured by Smart Automation. The X-axis torch carriage motor has a torque rating of 280 oz-in and the Y-axis gantry carriage motor has a torque rating of 420 oz-in.

CABLE ROUTING POLE

Each machine is equipped with a 2.5 ft tall steel swivel pole for support of the plasma torch cable when cutting.