BUILD YOUR MR-1 CNC MILLING MACHINE™

Orders placed today are estimated to ship in 1 week. Pre-assembled MR-1 Machine orders are expected to ship within 3-4 weeks of the order date. Freight shipping costs will vary based on location, required services, and carrier rates at the time of shipment (est. $300-500). Be sure to read and understand the MR-1 Shipment Details before placing your order.

Download Quote

Enter your name and email below to download a PDF quote of this order. Langmuir Systems may reach out to answer any questions you may have about this purchase.

Base Machine

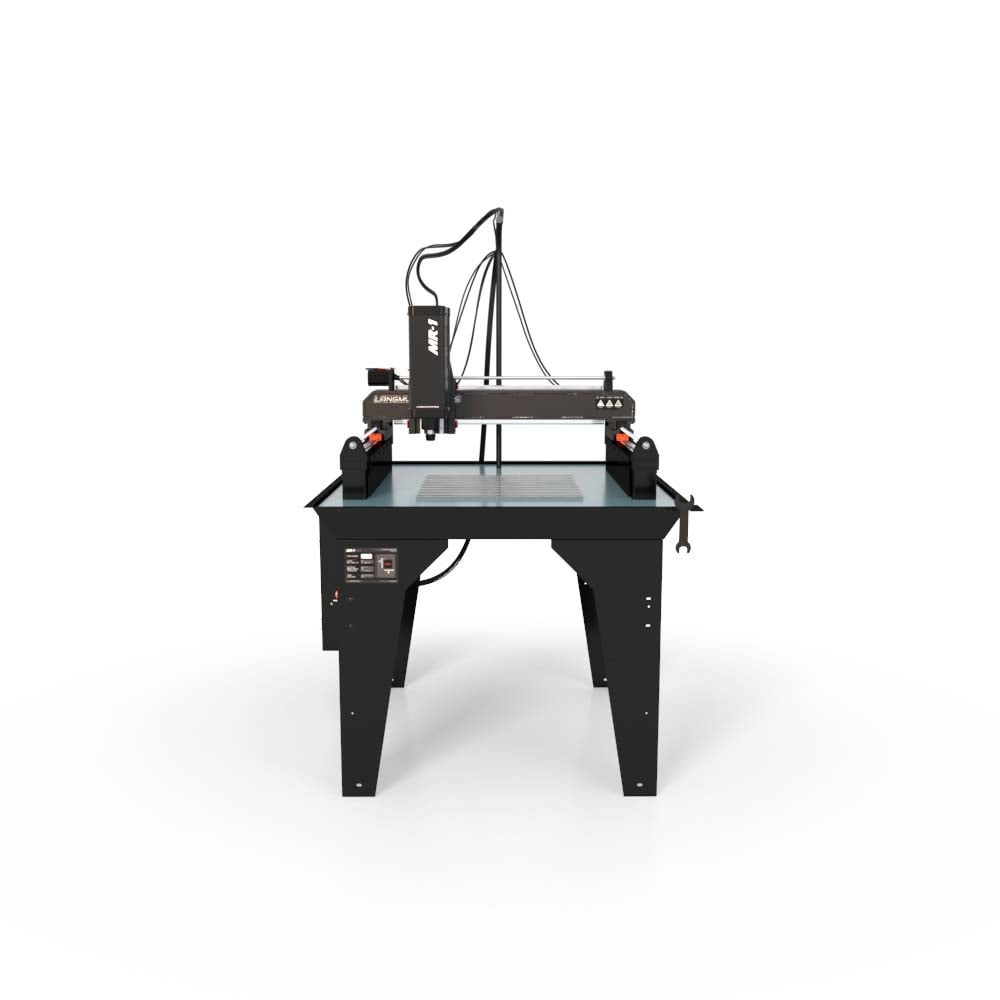

MR-1 CNC Gantry Milling Machine

$4495

Includes:

- MR-1 CNC Gantry Milling Machine

- Motion Electronics package including the following: Waterproof NEMA 23 stepper drive motors, Limit switch kit for each axis, Touch Probe and Tool Setter ports, Expansion ports for future add-ons, E-stop Switch, and High Speed USB Connectivity (Windows or Mac Compatible)

- 3.4hp 220V AC Servo spindle with 0-8000 RPM speed range - adjustable in software

- ⅛ and ¼ Precision ER20 Collets and 2 Collet Wrenches

- All miscellaneous parts and hardware required to assemble a ready-to-run machine. Note: Does not include concrete required for the base. Seven 50lb bags of concrete must be purchased separately from a local home improvement store. To learn more about the concrete reinforced base design and more information on this assembly step, please visit MR-1 Base Design.

- Co-Planarity Check Gage - now standard on MR-1

The MR-1 Gantry Mill stands alone as the only machine in its price class that is capable of productively machining aluminum, steel, titanium, and stainless steel. MR-1 is not a toy; it is a machine that you can rely on to make real metal parts that require excellent finishes, precision, and accuracy.

Let's start with the Hardware:

MR-1’s table is a nearly ¾” thick plate of 6061-T6 aluminum that is drilled and tapped for ¼-20 tooling holes in a 2”x2” grid pattern making workholding a breeze. The table is rigidly encased in 300 pounds of high strength interlocking concrete to promote excellent rigidity and stability. The base is designed to be skim cut flat by the user to produce a laser flat surface that is exactly parallel to the XY plane of the machine.

Four steel legs support the machine making it a freestanding unit. This means you don’t need to buy or build a workbench like most hobby machines. The legs come pre-drilled for attaching accessories such as leveling feet, computer stand, or touch screen controller (all available for purchase).

Also encased in the concrete base structure are the steel Y axis rail supports. To these mount the 1” thick steel Y axis rails containing the 20mm linear guideways. The direct connection to the concrete base structure keeps deflections to a bare minimum while providing a direct path for vibration damping.

Riding on the Y axis rails is the beefy X Axis gantry. There are no aluminum extrusions found here. The heavy duty gantry is constructed from 5/16” steel plate all the way around for maximum bending and torsional stiffness. It is machined and 100% inspected to exacting standards to hold a pair of 20mm linear guideways right where they need to be for supreme accuracy.

Keeping with the ‘aluminum has no place on the frame of a CNC mill’ theme, the X axis and Y axis carriages are made out of gray cast iron. The working surfaces are precision machined and 100% inspected to ensure that our quality requirements are met. Cast iron was chosen for its superior stiffness and vibration damping.

Machine travels are 23.0” (X), 21.0” (Y) and 6.1” (Z). An additional 2” of static Z-axis travel is available by adjusting the vertical spindle mounting position.

The Spindle:

The spindle motor is the heart of the machine, and we did not skimp here. The 220 V AC servo motor packs a whopping 3.4 horsepower and nearly constant torque from 0 to 4000 RPM. The 1:2 overdrive transmission allows the user to pick any cutting speed in software up to 8000 RPM. The built-in encoder means that the motor can maintain its programmed speed even under heavy loads.

When it comes to machining metals, torque is king and this beast of a spindle motor has plenty to give. Trim routers and low torque VFD driven spindle motors don’t belong on a machine designed for milling metal, especially steel. Our Spindle can run fly cutters, drills, boring heads, and large end mills. All without violating the SFM specs provided by the cutting tool manufacturers for carbide and high speed steel.

The spindle itself is custom made from high grade alloy steel and through-hardened for wear resistance. The ISO-ER20 taper of each is precision ground in-house to ensure runout is less than 0.0003”.

Don't have 220V power in your shop? Consider picking up a transformer to run our spindle motor on any ordinary 110V outlet.

The Electronics:

Pushing the spindle around are precision 1205 ball screws driven by NEMA 23 waterproof stepper motors. Each axis can exert over 135 pounds of cutting force that is reacted by 1” thick steel bearing mounts. This is sufficient for removing up to 30 pounds of steel per hour with the correct roughing tool and tool path setup. Maximum travel speeds of 100 inches per minute (IPM) ensure your projects get completed fast.

MR-1 not only comes standard with limit switches, it comes with two on the Y axis. This gives the machine automatic squaring capability of the gantry. Each time the user homes the machine in software, it will fine tune the alignment of the X axis to the Y axis on the fly to ensure squareness is achieved.

At the heart of the electronics is our proprietary motion control board with high speed USB communication. Based on the successful control boards from our CNC Plasma line of machines, this robust and battle tested system allows the user to stream millions of lines of code without skipping a beat.

The electronics box also includes ports to connect the Automatic Tool Setter and Touch Probe. The combination of these two devices allow the user to establish massively increased workflows by setting part locations and tool offsets automatically at the push of a button.

The Software:

Included with every machine is the CutControl software package that runs on both Windows and MAC OS. It takes the engine from our widely successful FireControl software and pairs it with the features required to blast through milling projects on MR-1, including a 3D visualizer. Control the machine at your fingertips including Spindle Control and RPM setting, Flood Coolant, Program Speed Overrides, Automatic Tool Setting, Touch Probing Routines, Milling Canned Cycles and many others. We are constantly adding new features and optimizations to improve the user experience of our software packages and this is no different with CutControl.

Product Link

Touchscreen & Control PC

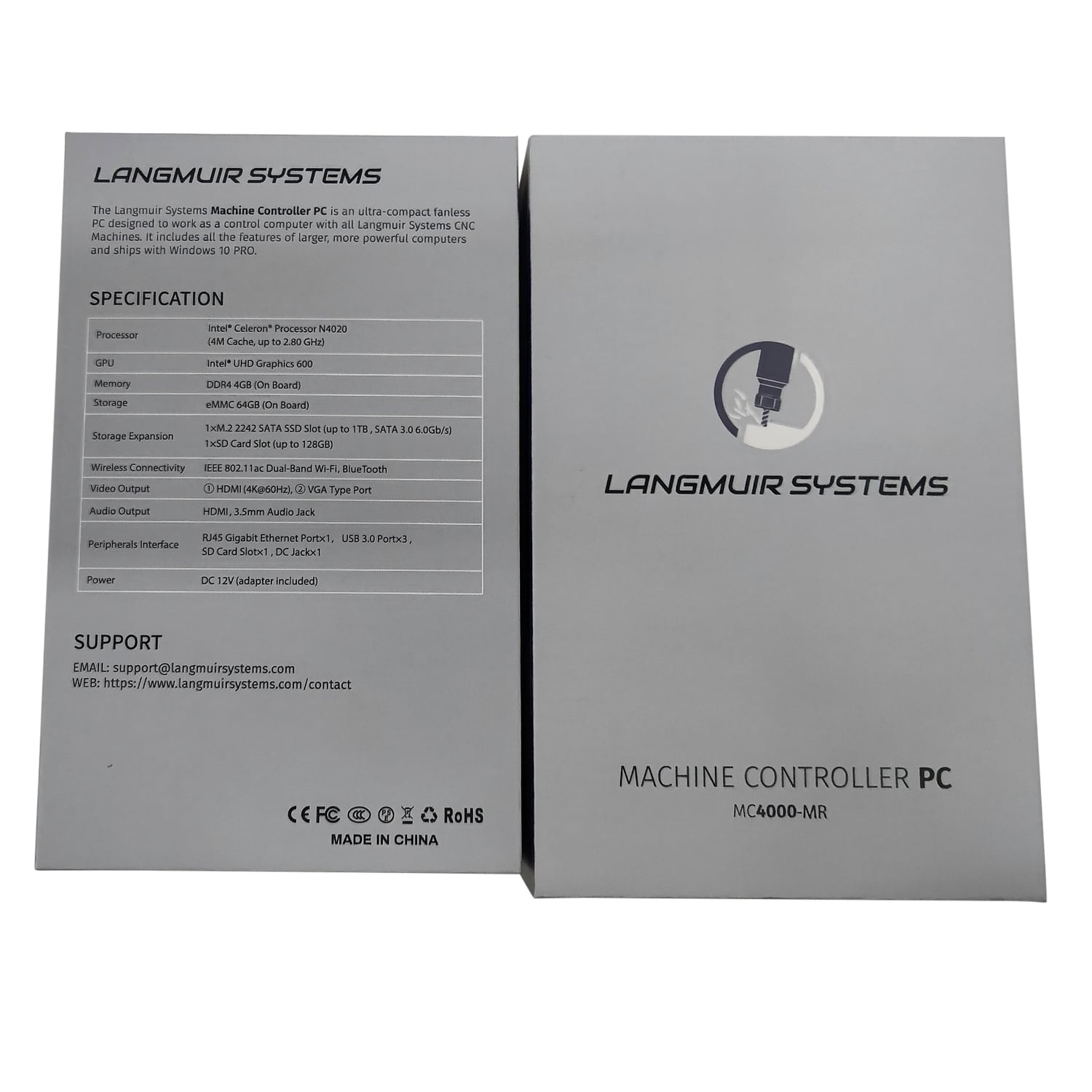

HD Touchscreen & Machine Controller PC Kit

$749.95

Includes:

- 21.5” FHD Touchscreen Monitor

- Control PC with Windows 10

- Steel Mounting Arm and Brackets

- Wireless Jog Pendant/Keyboard

- All necessary cables and hardware

The optional Touchscreen Controller Kit instantly increases the performance and user friendliness of your MR-1 machine and brings the experience closer to running a true CNC milling machine. Every CutControl function can easily be controlled via touch right on the screen. The Touchscreen is mounted on a swivel bracket so that the perfect viewing angle can be achieved for both seated and standing users.

The Control PC is specifically configured for use on MR-1 and comes pre-installed with Windows 10. It attaches directly to the back of the touchscreen in order to keep things tidy and the cabling short and out of the way. Programs can be loaded either via USB stick, or by simply taking advantage of the controllers WiFi to send and receive programs wirelessly from your design PC.

Setting work offsets, changing tools, and inspecting your projects requires the user to get up close and personal. Thanks to its 20’ connectivity radius, the wireless control pendant lets you control nearly every function of CutControl without having to physically be at the touchscreen.

Product Link

Machine Enclosure

MR-1 Sheet Metal Enclosure

$599.95

Includes:

- Front, back, and side panels

- Front doors, hinges, door pulls, and magnetic latches

- Front and Side Polycarbonate Windows

- All required fasteners

- 10.1 Oz Silicone Caulk Tube

The all steel powder coated MR-1 enclosure effectively contains flying chips and coolant during machining operations so that your work environment remains clean and safe. The front swinging doors allow plenty of access for loading tools and parts. Large windows in the doors and side panels allow unobstructed viewing access to the machining process.The side windows can be removed quickly with thumbscrews making maintenance and cleaning more ergonomic.

The enclosure has been purposely designed to minimize the number of possible leak paths by reducing the number of seams. A tube of silicone caulk is provided to ensure leak free joints between panels during assembly.

Product Link

Flood Coolant System

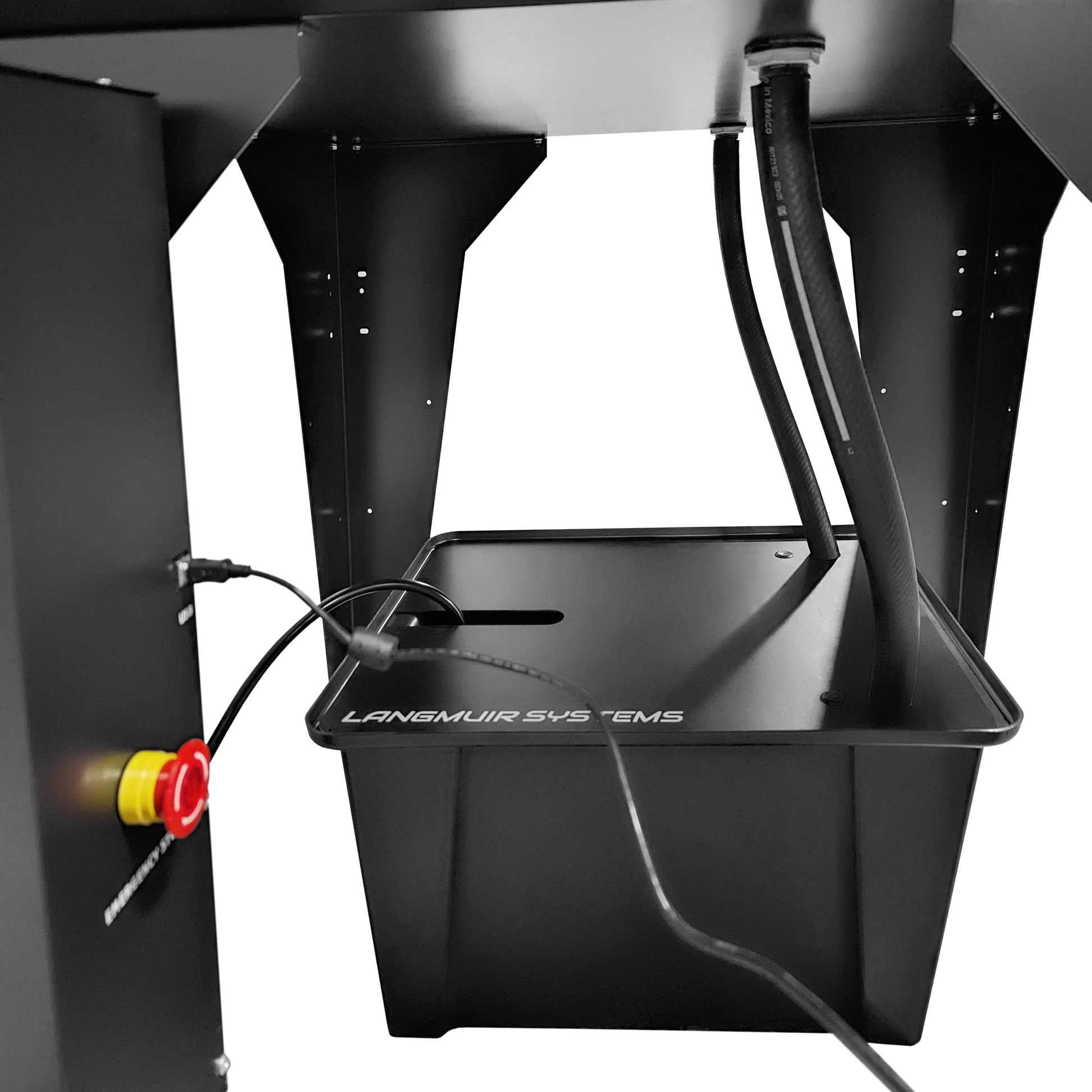

Complete Flood Coolant System for MR-1

$299.95

Includes:

- High flow submersible coolant pump

- 15 gallon coolant tank with steel lid

- Feed hose, loc line nozzle, and associated mounting brackets

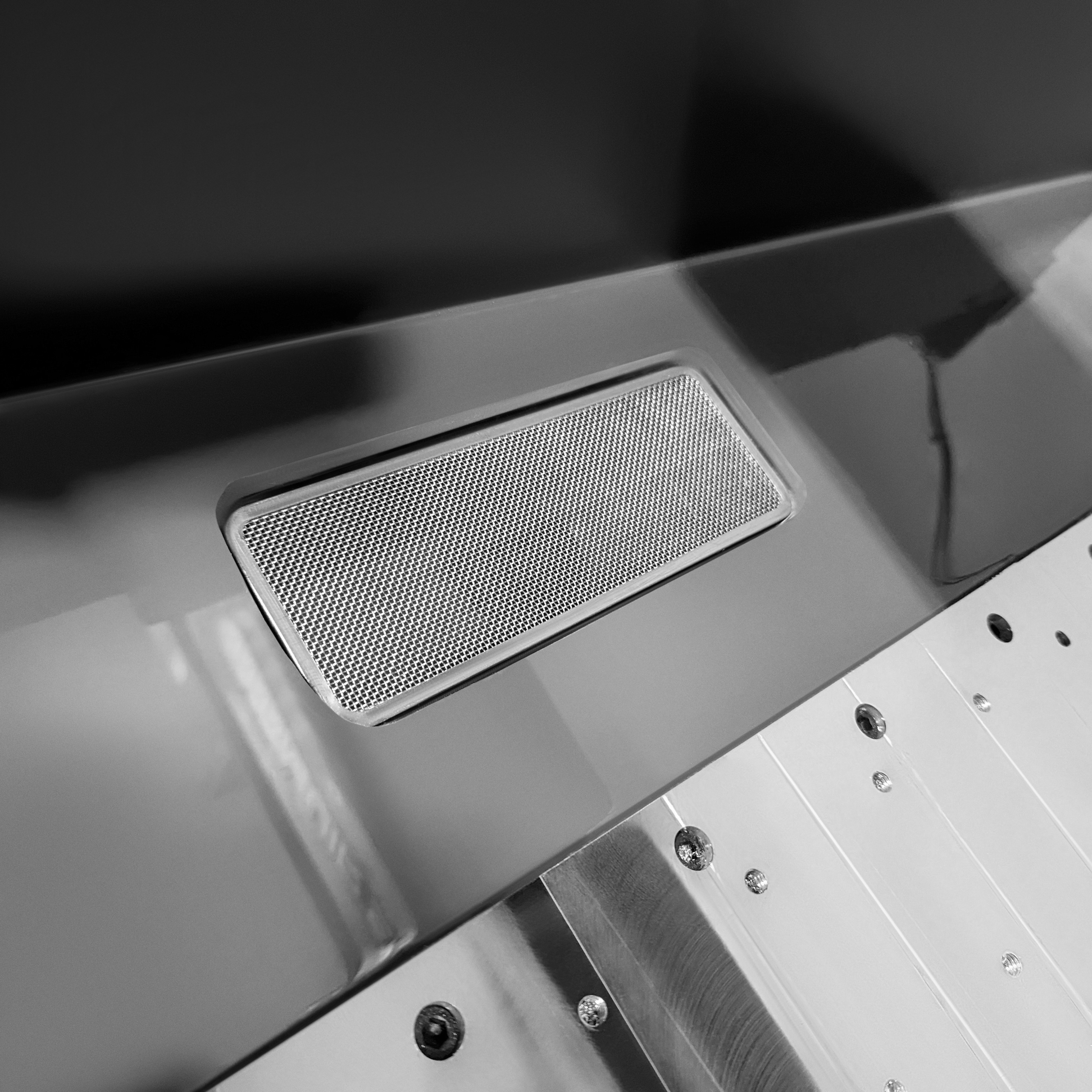

- 2 side drains, stainless wire mesh drain filters, and drain hoses

- All associated hardware and fittings

When it comes to machining materials like aluminum and stainless steel, flood coolant is a must have. Some will argue that mist coolant is an acceptable alternative, but research across the board shows that tool life, accuracy, and surface finish all benefit greatly from the use of flood coolant.

At the heart of the system is the powerful submersible pump that rests directly inside of the 15 gallon polymer coolant tank. With the ability to safely pump solids up to ⅛” in diameter, small debris and chips that get past the drain filters will cause no harm to the pump. The pump offers massive pressure and flow to blast away chips and keep your cutters completely flooded in coolant via the included loc-line nozzle with on/off valve.

This kit also includes all of the drain plumbing that is cast directly into the concrete base structure during assembly, much like the plumbing in slab foundation homes. Drains on either side of the base plate are protected by fine mesh stainless steel filters to ensure the drains will never clog with swarf.

We recommend picking up these other options with the flood coolant system:

- 1 Gallon Synthetic Multipurpose Cutting Coolant

- Leveling Feet Kit - Leveling the machine ensures that the coolant drain flow is equalized between the two drains

- Machine Enclosure

Note: If you're not purchasing the flood coolant kit, but think that may change in the future, we highly encourage you to purchase and install the flood coolant drain kit so that the drains can be installed at the time of assembly:

Product Link

Leveling Feet Kit

Precision Leveling Kit for MR-1

$79.95

Includes:

- Swivel type Steel leveling foot – qty. 4

- Aluminum leveling foot mount – qty. 4

- Mounting screws

The leveling feet attach to each leg on MR-1 and can be individually adjusted to level the machine at all four corners. This is especially important if you plan on running our Flood Coolant Kit to ensure that the machine is level to equalize flow to all four drains.

If you are planning to epoxy coat your base, we strongly recommend purchasing this kit. The self-leveling characteristics of the epoxy require the surface being coated to be level in order to work properly.

If you plan to move MR-1, we recommend purchasing this kit so that the machine can be releveled after moving.

Product Link

Computer Stand

Laptop or PC Stand for MR-1

$99.95

Includes:

- Computer stand tray

- Steel mounting arm

- All required fasteners

The Computer Stand attaches directly to the front left leg of the machine, providing a stable surface to place your control PC (such as a laptop).

Wanting more? Consider the Touchscreen Controller PC Kit or the Wireless Jog Pendant .

Product Link

MR-1 Full Assembly Service

The MR-1 CNC Gantry Mill Fully Assembled & Ready for Work.

$2495.95

The MR-1 Gantry Mill is designed to be as easy as possible to assemble. However, most users will need about 18-25 hours to complete the assembly from unboxing to first commissioning. If you don't want to spend time assembling the machine, or just want the quality assurance and reliability that comes with a factory assembled unit, consider purchasing the Full Assembly Service.

What's Included:

- Fully assembled MR-1 Machine that's ready to run upon delivery. Instead of concrete, we build each machine base in house using Epoxy Granite (EG). EG is an advanced material that has higher tensile strength and vibration damping characteristics as compared to standard concrete.

- Durable Epoxy Top Coat Finish is included at no additional cost.

- Most add-ons and enhancements that are purchased with you order will be installed by our team (such as the Leveling Feet Kit, Flood Coolant System, and Machine Enclosure).

- Oversized 5th drain placed behind the baseplates which utilizes a 1" diameter drain hose.

- Any add-ons and accessories that cannot be installed (such as the Control Kit) will be carefully packed and included in the final shipping crate.

- Full factory machine alignment (X axis to Y axis squareness, Z axis perpendicularity, and Travel distance compensation).

80+ point quality inspection followed by operational shakedown testing to make sure everything works as it should.

How it ships:

After assembly, forklift brackets are installed onto the legs and the entire 1100 pound machine is placed on a custom 5'x5' skid. Ratchet straps are then attached from the forklift brackets to eye bolts in the skid at each corner. An extra-thick cardboard box is placed over the machine for added protection during shipping.

All machines ship freight which includes lift gate service at the final destination.

A pallet jack can be used to move the machine around while it is on the skid. A forklift is required to remove the machine from the skid. If you do not have a forklift, you can choose to keep the machine permanently on the skid.

When it Ships:

Fully Assembled Machines currently ship in 3-4 weeks after order placement.

Product Link

High Powered Driver Upgrade

Increase driving force by 100%+

$99.95

Includes:

- High Powered Driver

Your MR-1 machine now ships standard with a High Powered Z-Axis driver. Plug and Play Upgrade to the Base Machine Electronics to increase any driver from 150lb of driving force to 350lb+. This upgrade can be added to either the X or Y Axis and is perfect if you plan to be machining steel or other hard materials. You will need 1 Driver to upgrade the X-Axis and 2 Drivers to upgrade the the Y-Axis.

Product Link

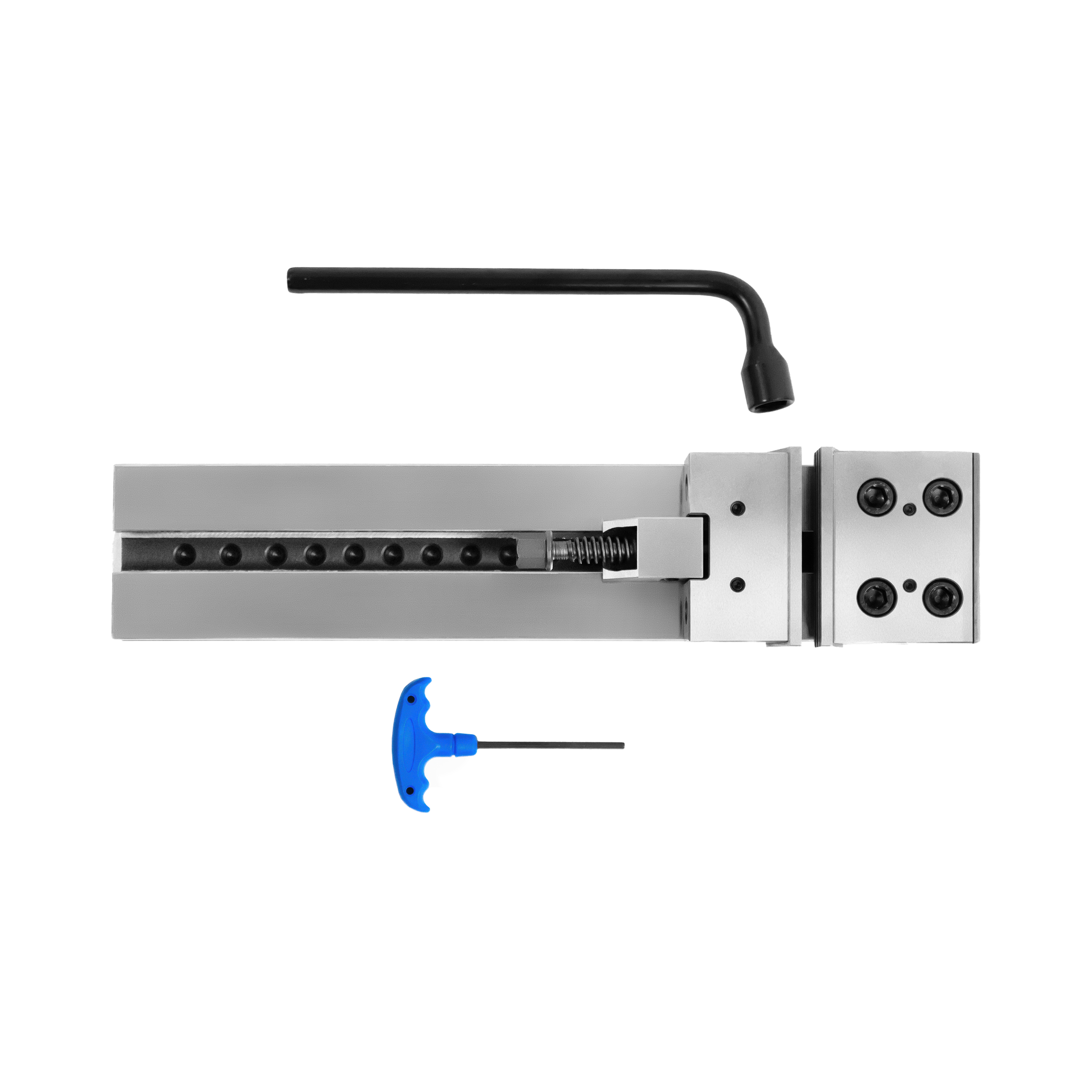

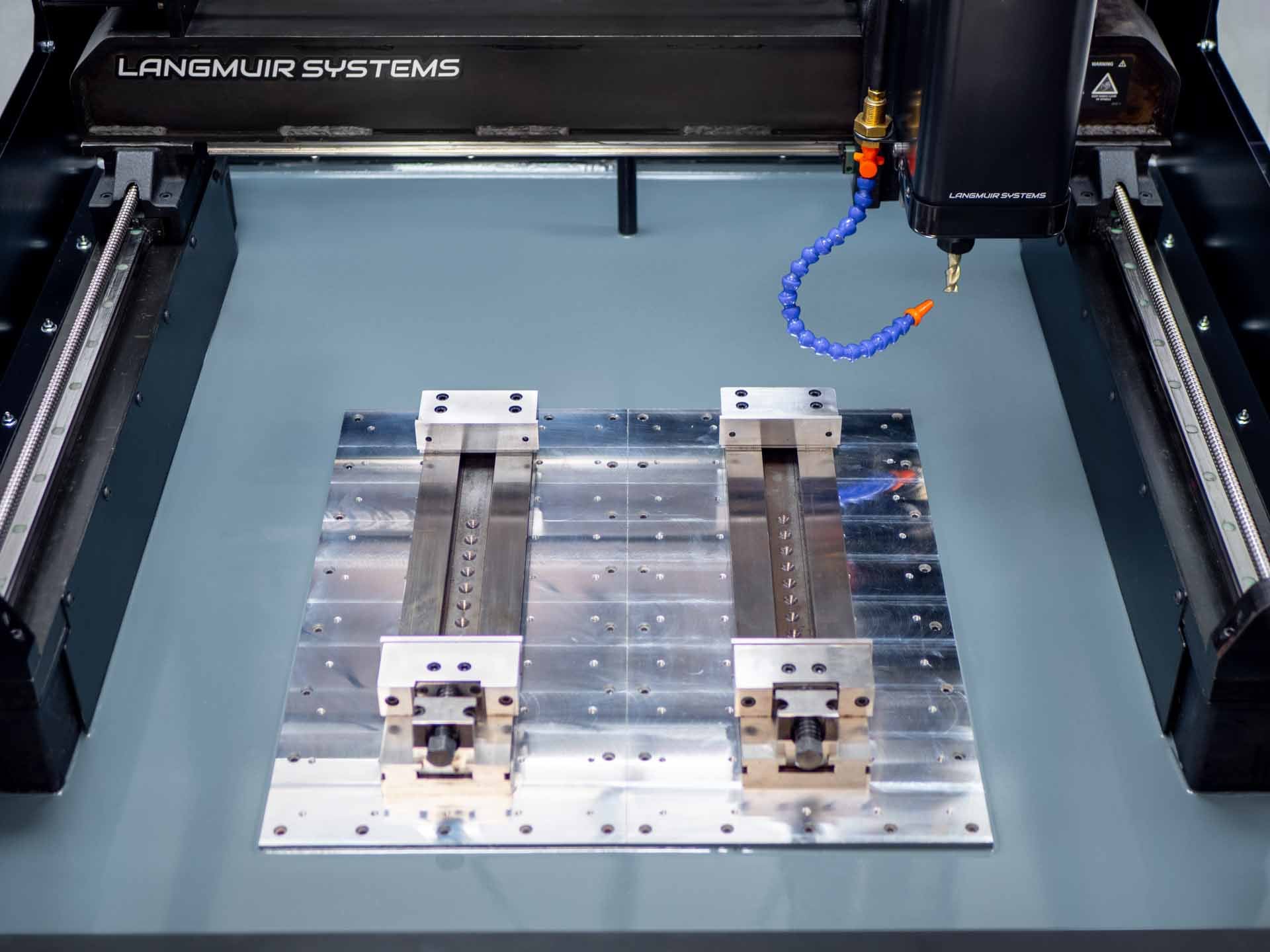

Low Profile Modular Vise

10" Low Profile Modular Vise

$389.95

Includes:

- 10” Modular Hardened Steel Vise

- Vise wrench

- T-handle

The Langmuir Systems 10” Modular Vise has been purpose built for optimal performance on MR-1. With a base height of only 1.1875 inches, the vise can accommodate parts as tall as 3.8” while still ensuring clearance to the bottom of the X axis carriage. All surfaces of the vise are heat treated and precision ground for excellent accuracy and durability.

While the vise can be attached using toe clamps, we recommend picking up a set of our purpose built vise clamps to secure to your base plate.

Why stop at one? Installing two vises allows even larger projects to be machined. Or set up two different projects in each vise and double your productivity.

Product Link

Toe Clamp Kit

Fast and Flexible Workholding Clamps

$99.95

Includes:

- Short toe clamp– qty. 5

- Long toe clamp– qty. 5

- Short step block– qty. 5

- Tall step block– qty. 5

- Short stud– qty. 5

- Medium stud– qty. 5

- Tall stud– qty. 3

- Flange Hex nut– qty. 10

- Coupling Nut– qty. 5

This toe clamp set is designed specifically for use on the MR-1 baseplate. Each toe clamp is machined out of tool steel and heat treated for excellent toughness and wear resistance. Step blocks can be stacked and arranged to clamp parts at effectively any height. The ¼-20 threaded studs can be connected using coupling nuts so that extremely tall parts can be securely clamped to the baseplate.

Product Link

Modular Vise Clamp Set

Modular Vise Hold Down Clamps

$59.95

Includes:

- Vise clamp– qty. 6

- Mounting fasteners– qty. 6

Purchase these clamps to secure your vise to the MR-1 baseplate. One set is needed per vise.

Note: These clamps are for the Langmuir Systems 10" Low Profile Modular Vise- NOT the SMW Mod Vise System.

Product Link

Baseplate Threaded Plugs

Keep Chips out of the Tooling Holes

$19.95

Includes:

- Threaded plug– qty. 100

Install these threaded plugs into the unused holes of your MR-1 baseplate to keep chips and debris out when not in use. Remove plugs as needed for clamping work or vises to the baseplate.

Product Link

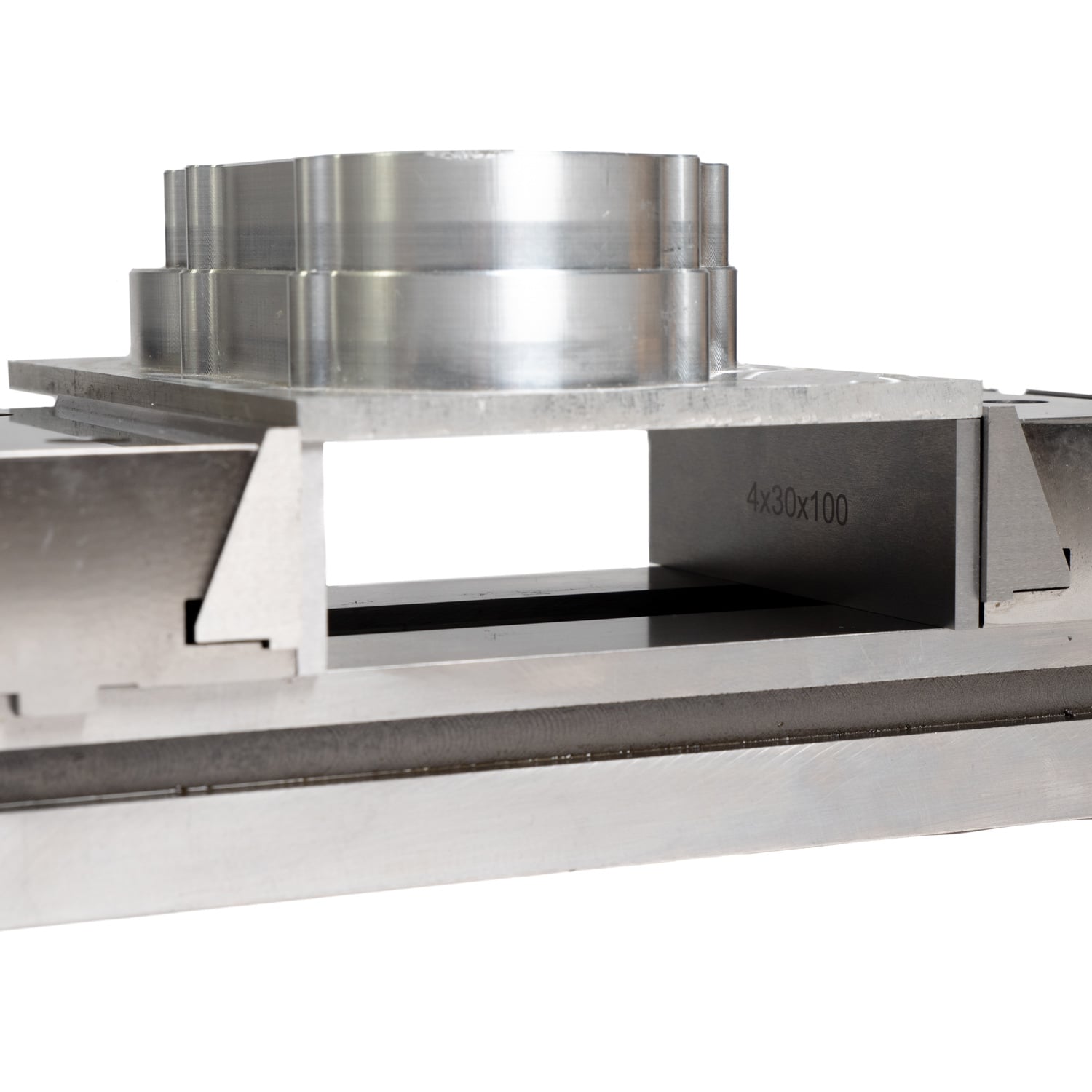

Modular Vise Parallel Set

Give the Low Profile Vise even more Versatility

$49.95

Includes:

- 6 precision parallel pairs 100mm x 4mm and 10,14,18,22,26,and 30mm height

- Protective storage case

The vise parallel set is intended to be used in combination with the Langmuir Systems modular vise. Each parallel measures 100mm wide and is made out of 4mm thick tool steel. All surfaces are precision ground and the heights held to .01mm accuracy.

Parallels are used to space the workpiece off of the base of the vise. Parallels are particularly useful for holding parts that are subsequently flipped and machined for later operations. We recommend watching our machining videos to see how parallels are used with our modular vises – we use them constantly when machining parts.

Note: This parallel set is compatible with both Vise Systems.

Product Link

Aluminum Soft Jaws

Elevate Your Machining and Precision with this

$29.95

Includes:

- Qty 2 precision machined aluminum soft jaw inserts

Remove the OEM hardened steel jaws and replace them with a set of aluminum soft jaws. Soft jaws can be machined as needed securely hold your parts for secondary machining operations. They are particularly useful for holding parts that can’t be held securely with modular fixturing methods.

The jaws are secured with the same hardware and springs that secure the hardened steel jaws.

Note: These soft jaws only fit Langmuir Systems vises that have four large socket head cap screws securing the fixed jaw holder to the base. Please ensure your MR-1 Low Profile Vise has the four socket head cap screws before ordering. Learn more about the MR-1 Low Profile Vise here!

Product Link

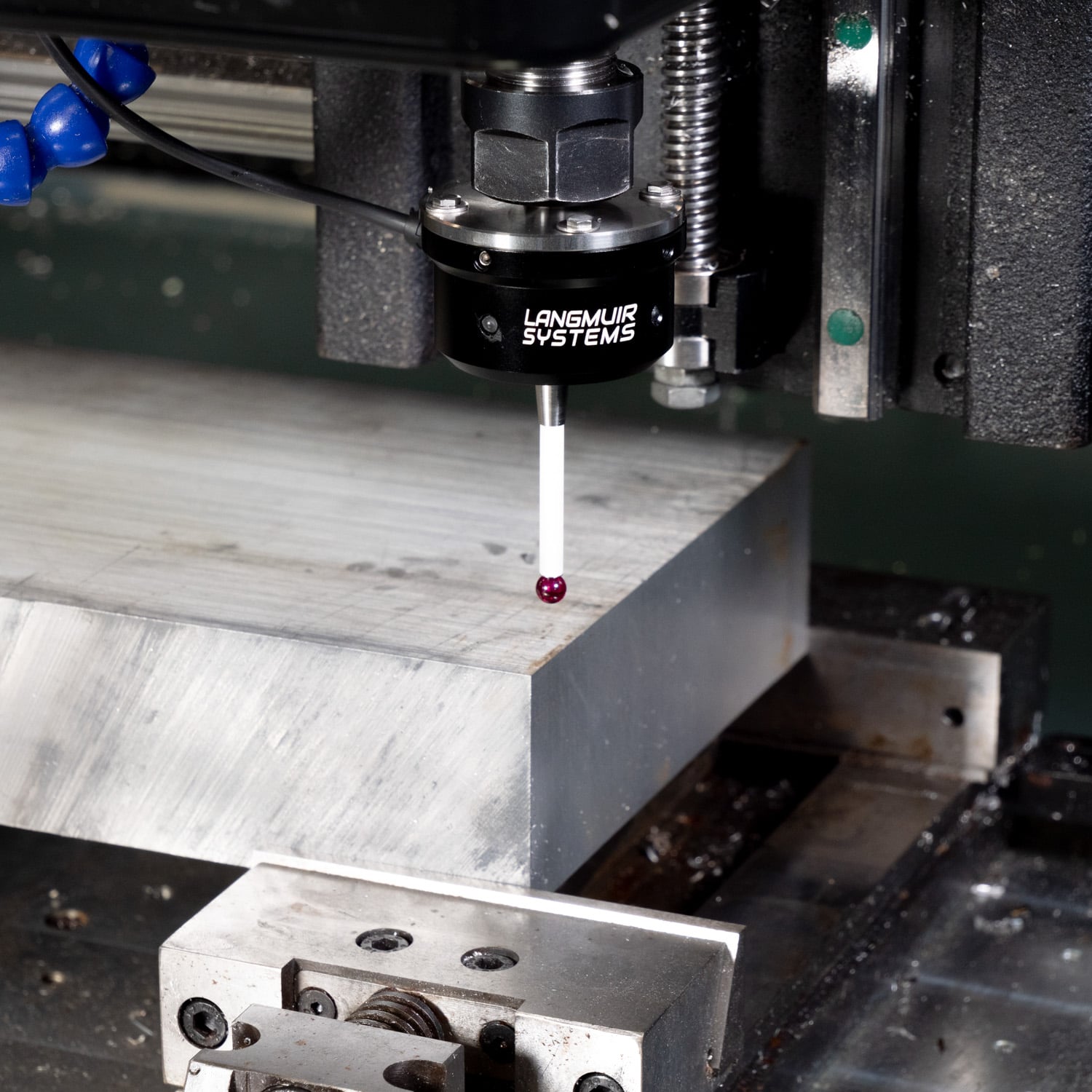

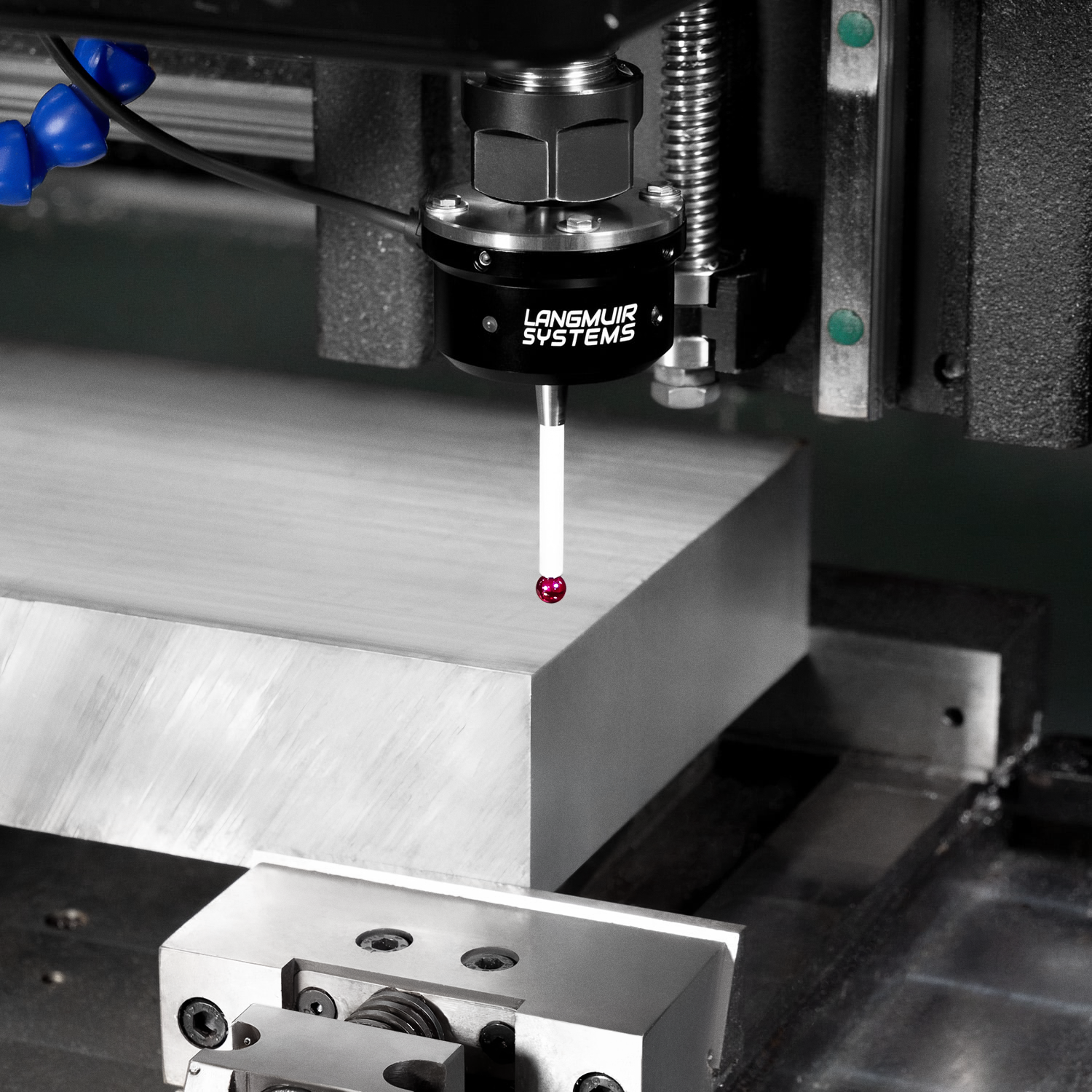

MR-1 - Electronic Touch Probe (V2)

MR-1 3-Axis Digital Touch Probe

$149.95

Includes:

- Redesigned Electronic Touch Probe with increased accuracy, repeatability, and reliability

- Ruby tipped carbide stylus, 1.25” long

- Cable to plug into CNC Electronics Enclosure

New and Improved! The Langmuir Systems V2 Touch Probe has been extensively redesigned to include a 3 pin kinematic mechanism that provides the following benefits:

- Ability to resolve position to less than .0005” accuracy

- Elimination of mechanical play present in some V1 probes

- Increased ease of disassembly and reassembly without compromising accuracy

With our custom designed touch probe you can quickly and automatically set work offsets using CutControl’s integrated probing canned cycles. Within less than a thousandth of an inch the probe will find the corner of a block, the center of a bore, the center of a slot, and much more. The probe can also serve as a useful inspection or digitizing tool for your projects.

The replaceable probe stylus is constructed of either carbide or ceramic for stiffness and is ruby tipped for wear resistance. Adjustment screws allow the tip to be adjusted to zero runout. The shank can be gripped using a standard ⅜” ER20 collet.

The probe contains four indicator lights letting the user know when the probe tip has made contact with the surface of the part.

Using the touch probe in conjunction with our tool setter will make the entire process of setting part offsets and tool offsets fully automated. Want both? Consider purchasing our bundle at a discounted price.

Product Link

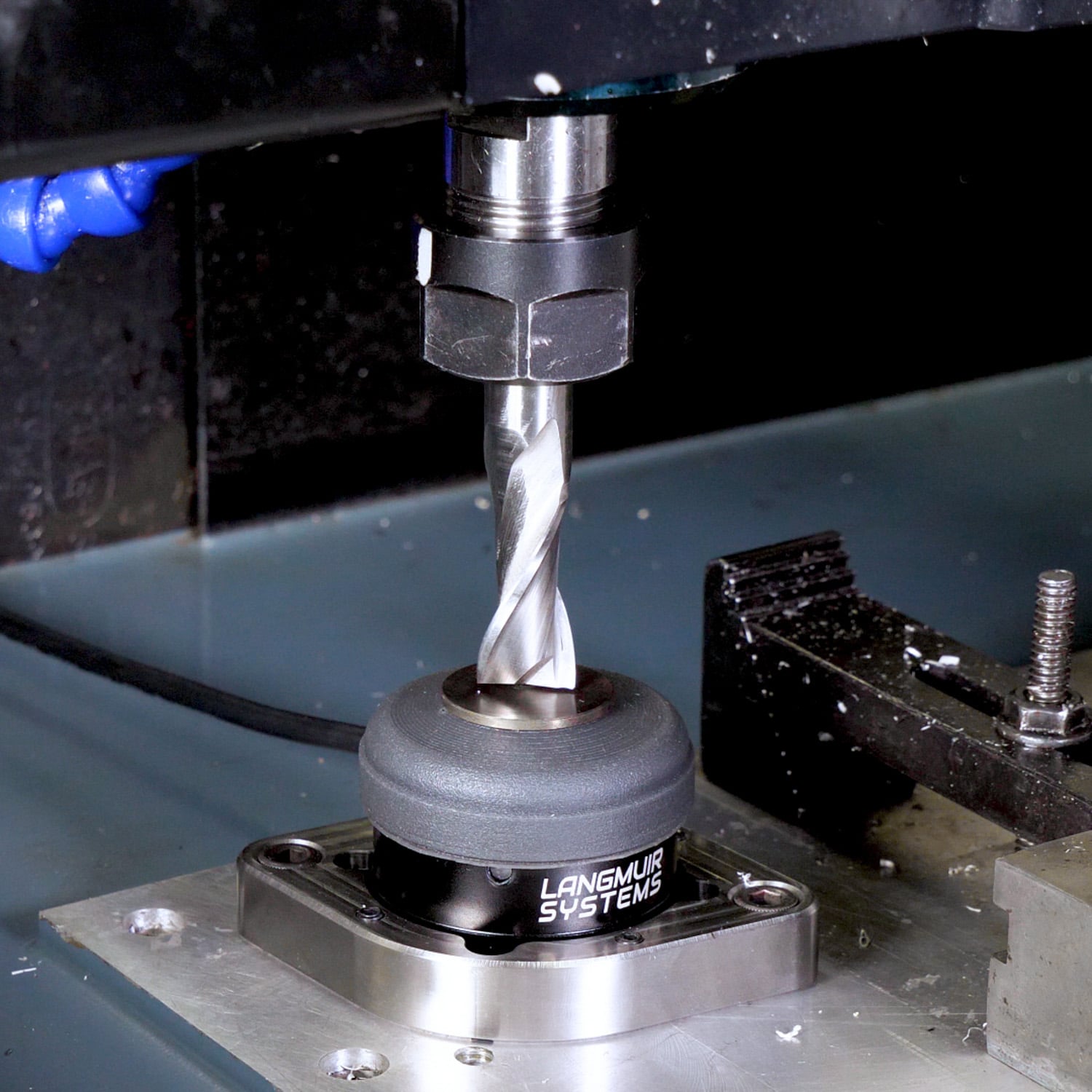

Automatic Tool Setter

MR-1 Automatic Tool Setter for Quick Tool Changes

$159.95

Includes:

- Electronic Tool Setter

- Cable to plug into CNC Electronics Enclosure

- Mounting hardware

No tool changer, no problem. With the Automatic Tool Setter make accurate tool changes at a productive pace on MR-1.

Before any machining can take place, CutControl must know where the tip of the tool is in relation to the part that is to be machined. While the option exists to manually touch the tip of the tool to the surface of the part, doing so is tedious and could cause damage to the tool or part if care is not used. When machining a part that requires many tool changes, the time used for manually touching off tools can quickly add up.

Using the Langmuir Systems Tool Setter not only saves time, but it also improves accuracy and repeatability. Thanks to its plug-and-play integration into CutControl, tool height is quickly and accurately sensed at the press of a single button. When machining complicated projects with multiple tools, the time saved can be substantial.

The waterproof design ensures that the Tool Setter can be safely used with the flood coolant system. The base includes mounting holes that match the tooling hole spacing on the baseplate so that it can be mounted anywhere that’s convenient and out of the way. Four adjustment screws allow the surface of the platen to be perfectly leveled to the XY plane of the machine. The Toolsetter contains four indicator lights letting the user know when the tool has made contact with the surface of the platen.

Using the Tool Setter in conjunction with our Touch Probe will make the entire process of setting part offsets and tool offsets fully automated. Want both? Consider purchasing our bundle at a discounted price.

Product Link

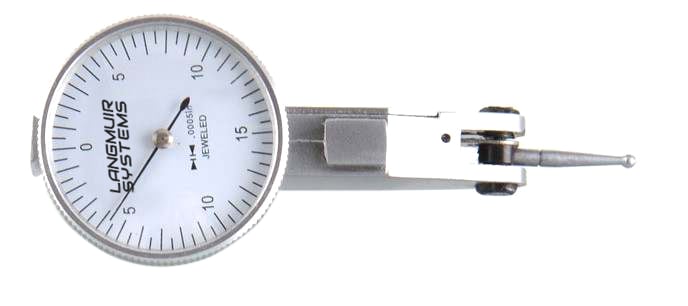

Dial Test Indicator W/ Base

Precision Measuring Tool for MR-1

$39.95

Includes:

- Dial test indicator

- Magnetic base

- Articulating arm

The dial test indicator is used for taking ultra precise measurements on the machine. Below are just a few uses:

- Checking the squareness of the X axis to the Y Axis.

- Squaring a vise so that the fixed jaw is parallel to either X axis or Y axis.

- Squaring a vise so that the fixed jaw is parallel to either X axis or Y axis.

- Comparing the relative height difference between two features.

- Checking the flatness of a part before or after machining.

The indicator tip has 0.030” range of motion and can resolve deviations as small as 0.0005”. The magnetic base allows the articulating arm to securely attach to any ferrous surface. The ball joints that connect the links of the articulating arm offer universal range of motion for coarse indicator tip positioning. The fine adjust knob allows the user to easily zero the indicator on the surface to be measured. The indicator can also be mounted in the spindle using a ⅜” collet.

Product Link

Tool Setter & Touch Probe Bundle

Get a Discount with this Bundle

$279.95

Includes:

- Automatic Tool Setter

- Electronic Touch Probe (Version 2)

Save time and money by purchasing our discounted Tool Setter & Touch Probe bundle for MR-1. Included in this bundle are one of each item. To learn more about each item, please visit the links below.

Product Link

NEW! Wireless Keypad Holder

Conveniently Store your Wireless Keypad

$14.95

Includes:

- Wireless Keypad Holder

- Magnetic Mounting Hardware

- Works with the MR-1 Wireless Jog Pendant (Sold Separately)

Designed to securely mount your wireless keypad, this holder keeps your workspace tidy while ensuring easy access whenever you need it. Say goodbye lost time looking for your wireless keypad and hello to seamless organization with our innovative holder.

Product Link

NEW! MR-1 - Toolsetter Riser

Reach New Heights with Our Tool Setter Riser

$24.95

Includes:

- 1.5" Toolsetter Riser

- Compatible with the MR-1 Automatic Tool Setter (Sold Separately)

If you typically use short reach tools with the spindle block in the 'up' position, you've probably encountered the situation where the tool cannot reach the tool setter without first running out of travel. Solve that problem by installing the 1.5” Tall Tool Setter Riser. Elevate your machining experience and unlock the full potential of your CNC setup with ease.

Product Link

NEW! MR-1 - Tramming Tool

Easily Achieve Accuracy and Precision

$14.95

Includes:

- Tramming Tool

- Compatible with the MR-1 Dial Test Indicator (Sold Separately)

This device allows the operator to directly measure spindle tram error so that the spindle can be shimmed/adjusted to eliminate the error.

Achieving exceptional surface finish with minimal steps between passes requires a spindle that has minimal tram error. Tram error is the measure of perpendicularity between the axis of the spindle and the XY plane of the machine. A spindle with too much tram error presents the cutting tool at an angle to the workpiece which has the tendency to create a stepped surface finish. The effect is magnified when using larger tools such as a fly cutter.

This tool sweeps an 8” diameter and should be used directly on the baseplate after it has been faced.

Product Link

NEW! MR-1 - Collet Wrench Holder

Effortlessly Change Tools with the Collet Wrench Holder

$11.95

Includes:

- Collet Wrench Holder

- Mounting Hardware

Tired of collet wrenches slipping during removal and replacement of tools? Purchase this accessory and enjoy trouble-free tool changes. This simple device engages one of the collet wrenches, leaving both hands free to operate the other.

Product Link

Collet Wrench / Blowgun Hanger

Convenient Place to Hang Your Tools

$14.95

Includes:

- Spaces for Vise Wrench, Vise Adjustment T-Handle, Collet Wrench, and Blowgun Hanger

- Mounting screws

Updated! This bracket offers a convenient location for storing your vise wrench, vise adjustment T-handle, collet wrench, and blowgun and your compressed air blowgun at the front right corner of the machine when not in use. The mount is designed to accommodate a wide variety of blowgun styles.

Product Link

Flood Coolant Drain Kit

Add Drain Plumbing to MR-1 Base

$34.95

Includes:

- 2 side drains and flange nuts

- Stainless wire mesh drain filters

- Drain hoses

If you do not currently have plans to run flood coolant, but think that may change in the future, you will need to purchase this kit. It allows you to install the various plumbing items and drains prior to pouring the concrete base of your machine.

Note: If you bought your MR-1 before April 22, 2024, installing this drain kit will require drilling two holes in your Chip Tray as explained in these instructions.

Note: If you are ordering the Flood Coolant System you do not need to purchase the drain kit because it is already included.

Product Link

Flood Coolant Relay Box

Control Flood Coolant ON/OFF in CutControl

$79.95

Includes:

- Flood Coolant Relay

- Required cabling for MR-1 CNC Box

The Flood Coolant Pump as standard comes with a manual on/off switch that is integrated into the power cable. If you desire the ability to turn the flood coolant pump on and off programmatically in CutControl, you will need this item. The flood coolant pump plugs into the relay box which plugs into a standard 120V outlet. A cable from the MR-1 electronics cabinet plugs into the relay and carries the on/off command signals. This is especially convenient when running programs so that flood coolant turns ON and OFF with gcode from your cutting program automatically.

Product Link

Pro Marine Epoxy Kit

Float the MR-1 Base with a Durable Epoxy Finish

$99.95

Includes:

- ½ Gallon Of Epoxy Part A

- ½ Gallon Of Epoxy Part B (Factory Dyed Machine Grey)

This kit provides everything needed to apply a protective epoxy surface to the concrete base. While not required on your MR-1 machine, the epoxy leveling kit has many benefits:

- The epoxy self leveling characteristics help to create a near perfectly flat surface that fills in any low spots in the concrete and creates a smooth to the corner drains when running flood coolant.

- It seals the concrete from water and coolant

- It seals the concrete from water and coolant

- The smooth nonporous surface is easy to clean between projects and looks visually appealing

This 1 gallon epoxy kit is very simple to apply. Simply mix part A & part B. Pour it evenly over the entire surface of the cured concrete until it is fully encapsulated. The epoxy is self leveling and will even out to create a near perfectly flat surface. Curing takes approximately 12 hours to reach full hardness.

Note: Concrete must cure for 5 days before applying epoxy.

Product Link

Fusion Flood Coolant

Keep Tools Cool and Happy with Fusion Flood Coolant

$49.95

Includes:

- 1 Gallon of Milling Coolant (concentrate)

Fusion is crafted as a biodegradable, semi-synthetic cutting fluid, offering seamless disposal without compromising its effectiveness. Fusion has excellent rust protection and unparalleled boundary lubrication and is completely free from sulfur, nitrates, mineral oils, and heavy-duty salts.

Forming a robust barrier, Fusion safeguards your tooling from the corrosive effects of moisture and other environmental factors. Fusion's boundary lubrication results in smoother machining operations, reduced friction, and enhanced tool life. With hassle-free disposal, Fusion is the only brand of cutting fluid that we recommend for use on the MR-1.

Fusion coolant is a 1 gallon concentrate. Simply pour 1 gallon of coolant concentrate into your 15 Gallon Coolant tank to achieve the correct dilution ratio.

Product Link

120V Spindle Transformer

No 220V, No problem. Run MR-1 on a Standard Outlet

$119.95

Includes:

- 2000W Transformer

- All required power cords

Purchase this item if your workspace is not equipped with 240V single phase AC power for the spindle motor. This transformer steps 120V outlet power up to 240V that is needed to power the MR-1 spindle motor. Note: Peak spindle power is limited to 2.0 hp (1.5kW) on a standard 15 amp outlet.

Product Link

Wireless Jog Pendant

Streamline your Work Flow with Wireless Control

$19.95

Includes:

- Wireless Jog Pendant

- USB Charging Cable

The wireless jog pendant allows the user to control nearly all functions of CutControl wirelessly within a 20 foot radius. This is especially handy when jogging, setting offsets, truing vises, loading tools, and manually cutting.

Product Link

MR-1 Part Stop Kit for Low Profile Vise

Maximize Repeatability with the Adjustable Part Stop

$44.95

Includes:

- Part Stop Arm

- Mounting Hardware

- Compatible with the MR-1 Low Profile Modular Vise (sold separately)

Install up to two part stops onto your modular vise and enjoy consistent and reliable part positioning for prototype and production work. The links are made out of 6061-T6 Aluminum for rigidity and incorporate nylon washers in the joints to allow the part stop to be easily swung out of the way when not needed.

Note: The Part Stop Kit will only fit Langmuir Systems vises that have four large socket head cap screws securing the fixed jaw holder to the base. Please ensure your MR-1 Low Profile Vise has the four socket head cap screws before ordering. Learn more about the MR-1 Low Profile Vise here!

Product Link

MR-1 Wash Down Hose Kit

Quickly and Efficiently Clean Out Your MR-1

$54.95

Includes:

- Garden Hose Nozzle

- Hose, Adapter, On/Off Valve, T-Fitting

- Hose Clamps

- Garden Hose Nozzle Hanger

This add-on includes all items needed to add a washdown hose set up to your machine. Simply connect to your machine's existing coolant line with the provided tee-fitting. The kit features a durable pistol grip garden nozzle, ideal for effectively cleaning the machine's interior, parts, and fixtures.

Note: The MR-1 Wash Down Hose Kit requires installation of the Flood Coolant System for use.

Product Link

MR-1 Lift Kit

Need to Move Your MR-1? Use the Lift Kit!

$149.95

Includes:

- Forklift Bracket (2)

- MR-1 Leg Braces (8)

- Fastening Hardware

Ensure the safety and stability for your MR-1 CNC Gantry Mill with our comprehensive lift kit. Designed to safeguard your valuable equipment during movements and relocations, this kit includes two forklift brackets and eight leg braces. With this accessory, you can confidently transport your MR-1 CNC Gantry Mill knowing that it is securely supported and protected at all times.

Please reference assembly document for the MR-1 Lift Kit for details on the assembly (linked here).

Product Link

Remote Emergency Stop Kit

$19.95

Includes:

- 1x Extension Cable Assembly

- 1x Emergency Stop Housing

- 1x Mounting Bracket

- Mounting Hardware

This kit includes everything needed to remove the Emergency Stop switch from your electronics box and relocate to the front of the machine where it is readily accessible.

Assembly instructions for relocating the Emergency Stop switch can be located here.

Product Link

Inner Door Window Kit

$99.95

Includes:

- 2x Inner Door Panels

- 2x Polycarbonate Door Windows

- Mounting Hardware

Install the Inner Door Window kit on an existing MR-1 enclosure to prevent water from dripping onto the floor when you open the doors. This kit includes new inner door panels, an extra set of polycarbonate door windows, and mounting hardware. Added bonus: no more chips in the doors either!

Assembly instructions for the interior door window kit can be located here

Product Link

6061-T6 Aluminum Billet (6"x4"x2")

Dimensions: 6 Inch x 4 Inch x 2 Inch

$24.95

Weight: 4.7 lbs

Material: 6061-T6 Aluminum Billet, Solid Stock, Saw Cut on Both Lengths

Product Link

ER20 Straight Shank Extender

ER20 Straight Shank Extender

$39.95

Includes:

- 1x ER20 Collet

- 1x Straight Shank Adapter

Optimize your MR-1 system with our ER20 Straight Shank Extender. The extender allows you to reach the baseplate when the spindle block is in the 'up' position, which maximizes clearance and saves you valuable set up time. This adapter features a 1/2" collet to ensure a secure fit. Engineered for precision and durability, it maintains accuracy and gives you the flexibility for any job.

Upgrade your setup with this essential extender for enhanced flexibility. Don't forget to check out our MR-1 Fly Cutter for facing large aluminum projects.

Product Link

Precision ER20 Collet Set

Precision Ground ER20 Collet Set

$89.95

Includes:

- ER20 collets of the following sizes: 1/16", 3/32", 1/8", 5/32", 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 13/32", 7/16", 1/2

- Protective Case

ER20 Collets are devices that get installed into the spindle taper of MR-1 to allow it to secure any tool with shank diameter between 1/16” and ½”.

When it comes to collets, not all are created equal. Blindly ordering the cheapest set that you can find is bound to cause headaches down the road. Our premium collets are guaranteed to not have more than 0.0003” of runout as measured at the nose of the collet. Low runout is a necessity for achieving good tool life, surface finish, and part accuracy.

Product Link

Fly Cutter

The Ultimate Aluminum Facing Tool for MR-1

$99.95

Includes:

- Fly Cutter body

- Insert tool holder

- Two aluminum cutting inserts (each with 4 corners)

The Fly Cutter is the best choice for facing large aluminum projects that require mirror-like surface finish. The tool can be set to cut up to a 2.5” diameter. It’s equipped with a ½” straight shank for use with a standard ½” collet. Maximum RPM is 2500.

Two sharpened and polished SEHT inserts are provided, each containing four cutting edges.

Product Link

Fly Cutter Inserts - 10 Pack

Compatible with our Fly Cutter

$79.95

Includes:

- Pack of 10 aluminum cutting carbide inserts in plastic case

Each pack contains 10 SEHT polished and sharpened aluminum cutting inserts. These inserts are made specifically for use with the Langmuir Systems Flycutter.

Each insert contains four cutting edges and can be rotated for more tool life.

Product Link

Ferrous End Mill Kit

The Perfect Starter Kit for Milling Steel

$124.95

Includes:

- ⅛”. ¼”, ⅜”, and ½” 4 flute variable flute and pitch AlTiN coated carbide end mills

For the best performance possible on our machines, we recommend using Langmuir Systems end mills exclusively. Our end mills are purposely designed and manufactured specifically for MR-1 for high material removal rates, accuracy, and surface finish. The variable pitch and variable flute geometries help to greatly reduce resonance and vibration when roughing and finishing ferrous materials on our machine. The AlTiN coating will ensure long service life when machining ferrous materials such as steel, iron, and stainless.

Product Link

Non-Ferrous End Mill Kit

The Perfect Starter Kit for Milling Aluminum

$124.95

Includes:

- ⅛”. ¼”, ⅜”, and 1/2" 2-flute, variable flute and pitch DLC coated carbide end mills

For the best performance possible on our machines, we recommend using Langmuir Systems end mills exclusively. Our end mills are designed and manufactured specifically for MR-1 for high material removal rates, accuracy, and surface finish. Thes variable pitch and variable flute geometries help to greatly reduce resonance and vibration when roughing and finishing non-ferrous materials. The ZrN coating will ensure long service life when machining non-ferrous materials such as aluminum, brass, and plastic.

Product Link

Ferrous Ball Mill Kit

Take Steel Surfacing to the Next Level

$79.95

Includes:

- ⅛”. ¼”, and ⅜” 4 flute variable flute and pitch AlTiN coated carbide ball end mills

For the best performance possible on our machines, we recommend using Langmuir Systems end mills exclusively. Our end mills are designed and manufactured specifically for MR-1 for high material removal rates, accuracy, and surface finish. The variable pitch and variable flute geometries help to greatly reduce resonance and vibration when roughing and finishing ferrous materials. The AlTiN coating will ensure long service life when machining ferrous materials such as steel, iron, and stainless.

Product Link

Non-Ferrous Ball Mill Kit

Create 3D Contours in Soft Metals and Plastics

$79.95

Includes:

- ⅛”. ¼”, and ⅜” 2 flute variable flute and pitch ZrN coated carbide end mills

For the best performance possible on our machines, we recommend using Langmuir Systems end mills exclusively. Our end mills are designed and manufactured specifically for MR-1 for high material removal rates, accuracy, and surface finish. Thes variable pitch and variable flute geometries help to greatly reduce resonance and vibration when roughing and finishing non-ferrous materials. The ZrN coating will ensure long service life when machining non-ferrous materials such as aluminum, brass, and plastic.

Product Link

Thread Mill Kit

Make any Thread From #8 to 3/4"

$329

Includes:

- #8, #10, ¼, ⅜, ½, AND ¾ single profile thread mills

Thread mills are used to produce both ID and OD threads. Their single profile allows each tool to produce a wide range of thread classifications. This set will produce any size thread between #8 and ¾”. They can be safely used on ferrous and non-ferrous materials.

For more specific information for each thread mill in this kit, please visit the product pages for the individual thread mills.

Product Link

#8 Thread Mill

AlTiN Coated

$24.95

Includes:

- #8 Thread Mill

While designed specifically to produce #8 threads with 32-56 thread per inch, this single profile thread mill can produce a wide range of metric and custom threads as well. Works equally well on both ID and OD threading applications.

Cutter Diameter: .120”

Neck Diameter: .070

Maximum Thread Depth: .025

Shank Diameter: .125”

Length of Cut: .500”

Overall Length: 2.000”

Coating: AlTiN

Product Link

#10 Thread Mill

AlTiN Coated

$34.95

Includes:

- #10 Thread Mill

While designed specifically to produce #10 threads with 24-56 threads per inch, this single profile thread mill can produce a wide range of metric and custom threads as well. Works equally well on both ID and OD threading applications.

Cutter Diameter: .138”

Neck Diameter: .075”

Maximum Thread Depth: .032”

Shank Diameter: .188”

Length of Cut: .625

Overall Length: 2.000”

Coating: AlTiN

Product Link

1/4" Thread Mill

AlTiN Coated

$34.95

Includes:

- ¼” Thread Mill

While designed specifically to produce ¼” threads with 18-56 threads per inch, this single profile thread mill can produce a wide range of metric and custom threads as well. Works equally well on both ID and OD threading applications.

Cutter Diameter: .180

Neck Diameter: .115”

Maximum Thread Depth: .033”

Shank Diameter: .188”

Length of Cut: .750”

Overall Length: 2.000”

Coating: AlTiN

Product Link

3/8" Thread Mill

AlTiN Coated

$84.95

Includes:

- ⅜” Thread Mill

While designed specifically to produce 3/8” threads with 14-40 threads per inch, this single profile thread mill can produce a wide range of metric and custom threads as well. Works equally well on both ID and OD threading applications.

Cutter Diameter: .300”

Neck Diameter: .218”

Maximum Thread Depth: .041”

Shank Diameter: .375”

Length of Cut: 1.000”

Overall Length: 2.500”

Coating: AlTiN

Product Link

1/2" Thread Mill

AlTiN Coated

$109.95

Includes:

- 1/2” Thread Mill

While designed specifically to produce 1/2” threads with 12-32 threads per inch, this single profile thread mill can produce a wide range of metric and custom threads as well. Works equally well on both ID and OD threading applications.

Cutter Diameter: .388”

Neck Diameter: .250”

Maximum Thread Depth: .069”

Shank Diameter: .500”

Length of Cut: 1.250”

Overall Length: 3.000”

Coating: AlTiN

Product Link

3/4" Thread Mill

AlTiN Coated

$109.95

Includes:

- 3/4” Thread Mill

While designed specifically to produce 3/4” threads with 10-32 threads per inch, this single profile thread mill can produce a wide range of metric and custom threads as well. Works equally well on both ID and OD threading applications.

Cutter Diameter: .495”

Neck Diameter: .340”

Maximum Thread Depth: .078”

Shank Diameter: .500”

Length of Cut: 1.375”

Overall Length: 3.000”

Coating: AlTiN

Product Link

Non-Ferrous 1/8" End Mill

DLC Coated, 2 Flute

$17.95

Includes:

- 1/8” End Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Square

Cutter Diameter: .125”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Non-Ferrous 1/4" End Mill

DLC Coated, 2 Flute

$26.95

Includes:

- 1/4” End Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Square

Cutter Diameter: .250”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Non-Ferrous 3/8" End Mill

DLC Coated, 2 Flute

$36.95

Includes:

- 3/8” End Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Square

Cutter Diameter: .375”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Non-Ferrous 1/2" End Mill

DLC Coated, 2 Flute

$54.95

Includes:

- 1/2” End Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Square

Cutter Diameter: .500”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Non-Ferrous 1/8" Ball Mill

DLC Coated, 2 Flute

$17.95

Includes:

- 1/8” Ball Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Ball

Cutter Diameter: .125”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Non-Ferrous 1/4" Ball Mill

DLC Coated, 2 Flute

$26.95

Includes:

- 1/4” Ball Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Ball

Cutter Diameter: .250”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Non-Ferrous 3/8" Ball Mill

DLC Coated, 2 Flute

$36.95

Includes:

- 3/8” Ball Mill

This cutter delivers consistent performance in non-ferrous metals like aluminum or brass.

Type: 2-Flute Carbide End Mill

End: Ball

Cutter Diameter: .375”

Flutes: 2, 45deg Variable

Coating: DLC

Product Link

Ferrous 1/8" End Mill

AlTiN Coated, 4 Flute

$17.95

Includes:

- 1/8” End Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Square

Cutter Diameter: .125”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous 1/4" End Mill

AlTiN Coated, 4 Flute

$26.95

Includes:

- 1/4” End Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Square

Cutter Diameter: .250”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous 3/8" End Mill

AlTiN Coated, 4 Flute

$36.95

Includes:

- 3/8” End Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Square

Cutter Diameter: .375”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous 1/2" End Mill

AlTiN Coated, 4 Flute

$54.95

Includes:

- 1/2” End Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Square

Cutter Diameter: .500”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous 1/8" Ball Mill

AlTiN Coated, 4 Flute

$17.95

Includes:

- 1/8” Ball Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Ball

Cutter Diameter: .125”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous 1/4" Ball Mill

AlTiN Coated, 4 Flute

$26.95

Includes:

- 1/4” Ball Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Ball

Cutter Diameter: .250”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous 3/8" Ball Mill

AlTiN Coated, 4 Flute

$36.95

Includes:

- 3/8” Ball Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Ball

Cutter Diameter: .375”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

Ferrous Roughing 3/8" End Mill

AlTiN Coated, 4 Flute

$36.95

Includes:

- 3/8” Roughing End Mill

This cutter delivers consistent performance in ferrous metals like steel.

Type: 4-Flute Carbide End Mill

End: Square (Roughing)

Cutter Diameter: .375”

Flutes: 4, 30deg Variable

Coating: AlTiN

Product Link

1/4" Chamfer Mill

The Perfect Tool for Corner Finishing

$19.95

Includes:

- ¼” 2 FLUTE CHAMFER MILL

This cutting tool is used to chamfer the corners of edges and holes. It can be used on both ferrous and non-ferrous materials. The 90 degree included angle produces 45 degree chamfers.

Product Link

Stub-Length Drill Index

Drill any Hole from 1/16" to 1/2"

$119.95

Includes:

- 1/16” to ½” drill in increments of 1/64”

This set of 29 drill bits includes all sizes between 1/16” and 1/2” in increments of 1/64”. The short length ensures that holes can be effectively drilled on taller parts. Each drill bit is ground from M2 tool steel and coated for wear and corrosion resistance. The drill point angle is 135 degrees.

Product Link

Extended Warranty Silver Plan

Add Extra Protection for your Machine. 1 Year Extension to Base Warranty

$399.95

Includes:

- 2 years of hardware protection

- 18 months of electronics coverage

Extra Protection. Zero Guesswork. The Langmuir Systems Silver Plan adds an extra layer of confidence to your CNC investment by extending your standard warranty by 1 full year. It’s the ideal choice for builders and professionals who want longer-lasting protection without compromise.

Whether you are running one-off custom jobs or daily production, the Silver Plan keeps you covered for defects in materials, workmanship, and manufacturing — giving you more uptime and fewer surprises. Enjoy the same great support, same coverage rules, and same peace of mind — just longer.

See Terms and Conditions for details. Exclusions apply.

Product Link

Extended Warranty Gold Plan

Our Best Coverage Plan. 3 Year Extension to Base Warranty, Expedited Shipping

$499.95

Includes:

- Industry-leading coverage – Up to 4 years of mechanical AND electrical protection and coverage

- Priority shipping – Expedited delivery of replacement parts to minimize downtime

- Front-of-line support – Your claims and service requests jump the queue

- Guaranteed performance – Every part backed by the same reliability and support you expect from Langmuir Systems

Our Best Coverage for Your Most Important Machine. The Langmuir Systems Gold Plan is the ultimate protection package for your CNC investment.

Designed for serious makers, professionals, and production shops, this plan extends your standard warranty coverage by an additional 3 years, offering peace of mind for the long haul

The Gold Plan ensures you can stay focused on your work, not your machine. Whether you are a small shop with big jobs or a builder with tight deadlines, this plan keeps your workflow moving and your machine performing like new.

See Terms and Conditions for details. Exclusions apply.

Product Link

Orders placed today are estimated to ship in 1-2 weeks. Pre-assembled MR-1 Machine orders are expected to ship within 8-10 weeks of the order date. Freight shipping costs will vary based on location, required services, and carrier rates at the time of shipment (est. $300-500). Be sure to read and understand the MR-1 Shipment Details before placing your order.